WhatsApp)

WhatsApp)

BLAST FINISHING Blasting is the process where small angular or spherical particles are propelled at a part by compressed air, or mechanical high speed rotating wheels ...

Cement history, in brief, from the Greeks and Romans to the development of Portland cement

Aug 08, 2017· The primary difference between concrete and cement is that concrete is a composite material made of water, aggregate, and cement. Cement is a .

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

International journal of advanced scientific and technical research Issue 4 volume 1, JanuaryFebruary 2014 Available online on ...

2 HPGR High pressure grinding roll for the minerals industry Introduction During its relatively short history in minerals processing, HPGR technology

coal hammer mill design[crusher and mill] Hammer Mill Design Mini Project – Free download as PDF File (.pdf), text . The basic design of the industrial hammer ...

In this instructable we will see how to make a chainsaw mill, how to use it, and discuss some tips and tricks to the hidden and mystical art of planking up fallen trees.

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction ...

Our Products. vibrating screen sale in africa – Gulin Machine Vibrating Screen machine in w. [ 04/09/2013 ] Conveyor belt splicing press from Jiangsu ...

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles.

Figure 2: The integrated cement plants and standalone cement grinding plants in the UAE in 2014, colourcoded by installed integrated cement production capacity in ...

Web portal for buildingrelated information with a "whole building" focus provided by the National Institute of Building Sciences. Areas include Design Guidance ...

ISSN: ISO 9001:2008 Certified International Journal of Engineering and Innovative Technology (IJEIT) Volume 3, Issue 5, November 2013

1 Schlumberger Fishing Services Perform casing backoff in vertical and horizontal wells Applications Replacing worn or damaged sections of uncemented

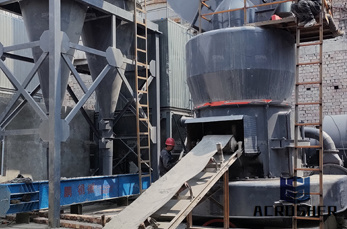

MILL SYSTEMS Main Features Proven Reliability 25 years design and operating experience Over 425 units worldwide Cost Savings Reduced specific power

Job Interview Practice Test Why Do You Want This Job? Answer this job interview question to determine if you are prepared for a successful job interview

industrial case study: the cement industry calmac study id: final report prepared for pacific gas and electric company san francisco, california

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

China Mill Machine manufacturers Select 2017 high quality Mill Machine products in best price from certified Chinese Automatic Machine manufacturers, Mill Equipment ...

Design features of rotary cement kilns ... Riveted construction continued until WWII. The technique of making welded joints in such heavy plate by arc welding ...

LargeScale Production of EdgeSelectively Functionalized Graphene Nanoplatelets via Ball Milling and Their Use as MetalFree Electrocatalysts for Oxygen .

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

WhatsApp)

WhatsApp)